|

| June 25, 2019 | Volume 15 Issue 24 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

The big lift

The new Three Gorges ship lift is the largest and most complex of its kind in the world. SKF partnered with the Changjiang Institute of Survey, Planning, Design and Research, the Chinese company responsible for its creation, in several important aspects of the project, supplying important components from plain, roller, and thrust bearings to hydraulic nuts, pumps, and other mounting and dismounting tools.

To anyone who sees it for the first time, the Three Gorges ship lift is more like a building than a device.

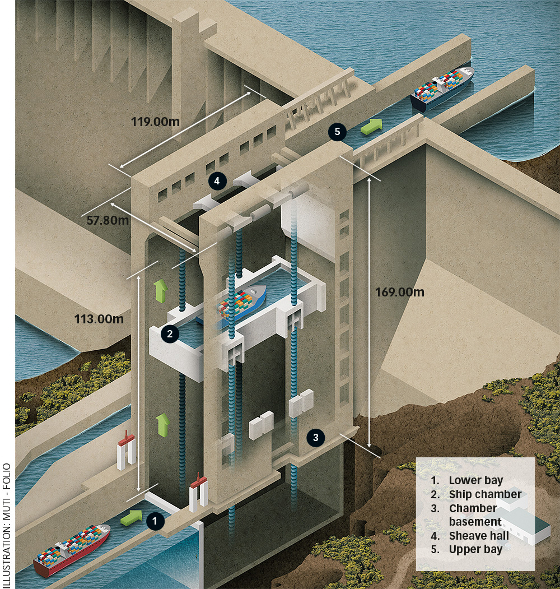

It has a maximum lifting height of 370 feet, enabling ships of 3,000 tons or more through. Its caisson and related facilities weigh about 17,000 tons, making it the largest and most complex ship lift in the world.

Theoretical research on the ship lift, the final part of the Three Gorges Project, began in the 1950s. Its design was completed in 2007, and trial operation began in September 2016.

The ship lift is built to improve the speed of dam passing for ships on the Yangtze River, according to Yu Qingkui, project manager of Three Gorges ship lift from the Changjiang Institute of Survey, Planning, Design and Research (CISPDR), affiliated with the Yangtze River Water Resources Commission. He says it now takes about 50 minutes for a ship of about 3,000 tons to go up or down the ship lift, as opposed to the 3.5 hours it would take using a five-level ship lock.

The Three Gorges ship lift has a maximum lifting height of 370 feet, allowing ships of 3,000 tons and more through. [Image courtesy: SKF]

Securing the safety of ships passing through the lift is crucial, Yu explains, and lifting such a heavy caisson to such a height requires precision balance. The Three Gorges ship lift has a counterweight system to balance the weight of the caisson, and a gear-and-rack system to drive the chamber up and down.

The 17,000-ton counterweight, the equivalent of a fully loaded caisson, is divided into 16 sets, evenly located in the twin towers at the sides of the caisson. The counterweight is connected to the caisson by 256 ropes (cables) via 128 double-rope pulleys at the top of the towers. These make sure that the caisson and the counterweight are in balance, no matter the position of the caisson. Four toothed racks are installed in the towers at each of the two sides of the caisson, from the bottom to the top. The caisson is driven up and down by four pinions that engage with these toothed racks.

Each pinion is driven by two electric motors. All drives are interconnected via synchronizing shafts under the caisson.

Thanks to the counterweight system, the pinions and toothed racks only carry about 440 tons of total weight instead of 17,000 tons, greatly improving efficiency and reducing energy costs.

Although the caisson is balanced by the counterweight system, an appropriate safety device is still needed because even a small accident could be catastrophic. On the advice of experts, CISPDR adopted a safety mechanism consisting of a nut post and short screw section (rotary locking rod). When the caisson experiences an unbalanced force, the driving units stop and the caisson is locked vertically by the safety mechanism, thus avoiding possible catastrophe in the event of an accident.

Double rope (cable) sheaves of the counterweight system, fitted with SKF Explorer spherical roller bearings. [Image courtesy: SKF]

After careful consideration and comparison of alternatives, CISPDR chose SKF spherical roller bearings and thrust bearings to be used for the ship lift's counterweight system, driving system and safety mechanism. They also used SKF spherical plain bearings for the caisson's hydraulic cylinders and tightrope locking system to make sure the lift system operates safely and reliably.

SKF also supplied hydraulic nuts and hydraulic pumps and other mounting and dismounting tools to increase the maintenance efficiency.

VIDEO: World's largest permanent ship lift is located at Three Gorges Dam in central China's Hubei Province. Jointly designed by Chinese and German experts, the ship lift is also the most sophisticated of its kind. Follow this first-ever aerial view of the facility to see how it works. [Source: New China TV -- Note: This video was added by Designfax]

CISPDR has had considerable technical cooperation and exchanges with SKF since the early stages of the Three Gorges ship lift project, and the company recognizes the high quality of SKF products and service.

Freddy Pan, SKF hydropower segment manager, explains that China Three Gorges Corp. is a key customer and that SKF has been providing technical consultation and on-site services for the operations and maintenance of the Three Gorges ship locks since 2012.

A formal business cooperation between the two companies started in 2014, a result, Yu says, of excellent product performance. "We are satisfied with SKF's products," he says. "SKF is very trustworthy and they can deliver the products in time."

The companies' cooperation is deepening. SKF is now not only a bearing supplier for the Three Gorges ship lift, but also a sealing solution provider for the bearing housings and other critical components of the ship lift. Three Gorges will continue the cooperation with SKF in the purchase of spare parts after the ship lift starts formal operation.

"We are proud to work with the world-famous Three Gorges Project," says SKF's Pan. "We have helped to solve many problems for the ship lift, making the impossible possible. The cooperation has set an industrial benchmark and is (a) win-win for both the Three Gorges Project and SKF."

Learn more about SKF solutions for design engineers -- including Bearings, Seals, Lubrication, Mechatronics, and more -- at www.skf.com/us/.

This article first appeared in SKF's Evolution magazine ISSUE 3 2018 and published online by SKF July 2018. It is reposted in Designfax with full permissions from SKF. Thanks, SKF! Read the latest issue of Evolution at http://evolution.skf.com/us/. It is filled with interesting applications, new products, and industry insights.

Published in Designfax June 2019

Rate this article

View our terms of use and privacy policy